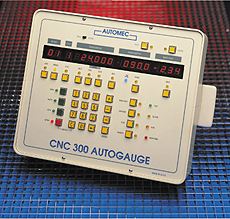

CNC Retrofit controls for press brakes and shears

Specialized in the area of retrofitting either existing or newly purchased pressbrakes and shears with simple, reliable, and cost effective gauging systems.

A control for Automec backgauges that can be programmed as simple as our popular CNC150 or it can be programmed to utilize an array of sophisticated functions. These systems are noted for their ease of programming, high reliability, and positioning accuracy.

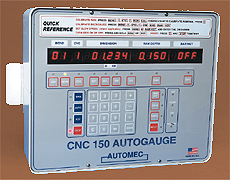

Tube deburring machines

Our diverse range of tube deburring machines gives you the right machine for your application. Burrmaster’s provide you with a full spectrum of choices for the wire brush deburring of your tubes or parts.

Electric CNC servo-drive press brakes

EXCLUSIVE CANADIAN DISTRIBUTOR

34” X 25 TON TO 10 FT X 100 TON CAPACITIES

3 AXIS (X,Y,R) & 5 AXIS (X,Y,R,Z1,Z2)

CNC SERVO DRIVE RAM CONTROL

0.0002” RAM REPEATABILITY

LASER GUARDS IN FRONT, SAFETY GATES SIDE & REAR

CSA ELECTRICS & PRS READY

HIGH SPEEDS, SAFE & ACCURATE

NO HYDRAULIC TANK, PUMP, VALVES OR LEAKAGE

MUCH LOWER ELECTRICAL COSTS THAN HYDRAULIC

![]()

Manual toggle, impact, pneumatic, mechanical air clutch

Synonymous of robustness, reliability and endurance, EMG presses have been used for more than 35 years in many sectors of differents industries:

Clock industry, jewellery, Spectacle industry, Switchgear, automotive Engineerings, Household electricals, toys, Iron work. All range EMG offers a broad choice of applications and adaptations.

![]()

Insertion presses

PennEngineering rolled out the first model of PEMSERTER® fastener insertion press in 1967, which introduced fabricators and OEMs to an entirely new method for installing self-clinching fasteners. The benefits of installation speed, quality, and cost reduction quickly became apparent and remain true to this day.

![]()

Sheet slitters and coil processing machines

Whether it is a standard off-the shelf machine or a custom machine, our craftsmen will provide their expertise and experience to provide you with a quality machine that will meet your needs.

![]()

Metal deburring machines and slag grinders

Predominantly used for thin sheet metal plates. These plates are usually 1 to 6 mm thick and made of steel, stainless steel or aluminium. Deburring is performed using rubber faced contact pressure rollers, brush rollers with wire or Scotchbrite brushes and disc stations. This grinding method operates dry or wet.

![]()

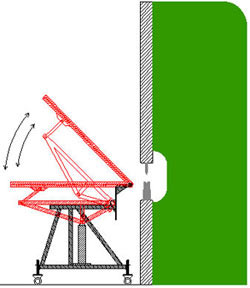

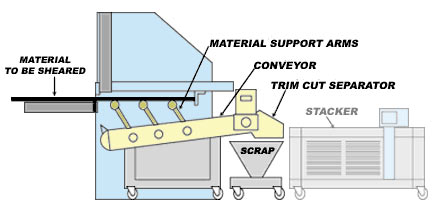

Squaring shear conveyors, stackers and sheet support custom fabricating and design

Met-Fab Manufacture – Pneumatic Sheet Support Units for Shears; Motorised Shear Conveyor Units; Stacker Units For Shears; Press Brake Front Supports.

![]()

Dry and wet metal deburring machines, wet dust collectors

Manufactures 4 different series of widebelt machines. Each series represent the belt length aswell as recommended duty of the machine.

![]()

Sheet metal machines, shears, foot and power, brakes, hand and box and pan

All products at National meet strict company and OSHA standards.